After talking to Tony (you remember…), I realized that my 9N’s 12V upgrade was probably just replacing the 6V battery with a 12V one and changing the ground from the original positive to the more normal (now-a-days) negative ground. Oh, and it looks like a resistor was added to the coil’s primary circuit to prevent it from burning out. The generator and probably the starter are 6V units. So I went ahead and ordered a 12V upgrade kit from Yesterday’s Tractors. It comes with a 12V alternator with internal regulator, a bracket to fit it to the motor, a 12V coil, wiring harness and instructions. So today’s tasks were to get ready to install these items when they arrive. I removed the old generator and the spark coil. While I was at it I decided to do the prep work for adding an oil line to the newish governor I got from Tony. It turns out that the oil filter has a short line from the bottom of the canister that contains it to the oil pan. Well according to Ford’s original instructions for upgrading to a governor with an oil feed all you have to do is remove that short line, plug the hole in the oil pan and run a line from the bottom of the oil filter to the governor. So after draining the oil filter canister and putting in a new filter that I had already bought, I removed the short line.

Here you can see the short line partially removed. A suitable length of brake line is all I need to finish that upgrade. I need to figure out how long the brake-turned-into-oil line should be. I’ll probably use some heavy wire like from a coat hanger as a surrogate to find the best route and length. Too bad the oil filter is on one side of the motor and the governor is on the other.

The one other thing I did (actually yesterday) was to sharpen the blades of the brush hog. I spent a good deal of time and effort trying to enlarge the hole in the desk of the unit to access the nuts that hold the blades one. Each blade is on one nut so that it is free to swing back if it hits and object that it can’t cut. I finally gave up after much grinding and cold-chiseling when I realized I didn’t have a socket that’s large enough for the nuts anyway.

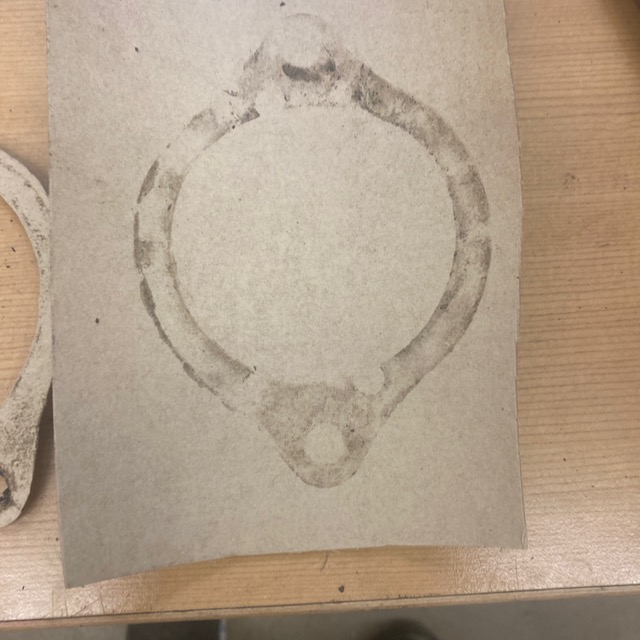

So I jacked up the back of the brush hog and put it on jack stands and using my brand new angle grinder went to work. A half hour or so of grinding put a reasonable edge on the two blade.

They don’t have to be sharp like lawn mower blades. An edge like that wouldn’t last anyway cutting small saplings and the like. But you don’t want the edges to be round like mine were.